20KN computerized iron ore pellet compression testing machine

1. Introduction and application of testing machine

l Adopting precise auto control and data acquisition system to realize fully digital adjustment to data acquisition and control process. It can test max. bearing tensile, compression, tensile strength, deformation, elongation and other technical specifications;

l After test, the above parameters can be calculated automatically through main controller according to the test parameters, which are set before test and meantime display the corresponding test results. All test parameters can be saved and inquired after test, also can be connected with printer to print test reports.

2. Main functions of testing machine:

l with function of automatic return to original position, intelligently, efficiently, quickly;

l with limit protection function of any working position and overvoltage, over current protection functions, reliable, safe;

l With strong test data, which can save, inquire and retrieve test data anytime.

l with many control modes of constant speed control to force, stress, deformation, strain, stroke, load, elongation, displacement and low cycle and user self-programming control;

l Switch among many test curves: stress-strain curve, load-time curve, deformation-time curve, load-displacement curve. Partial enlargement, overlap and comparison.

3. Introductions of test method

Definition

Crushing strength: the applied maximum compressive load at which an iron ore pellet is broken completely, and which is expressed as the mean value of all measurements of test sample.

Taking of sample

The test sample (test pieces) for determining the crushing strength shall by obtained at random, for example by the use of a random selection plate, on about 1kg of the sample for physical testing. The test sample shall be oven dried at 105±5℃ and cooled to room temperature before testing.

Number of test pieces (iron ore pellets)

Sixty or more test pieces, or as agreed upon between the interested parties, shall be tested for each sample.

Test procedure

Place a test piece (single pellet) at the approximate centre of the surface-hardened portion of the lower platen. Apply the load at a constant rate between 10 and 20mm/min throughout the test period.

Record the maximum load, at which the test piece undergoes complete breakage, to at least one decimal place, in decanewtons.

Note: complete breakage is ensured by continuing to apply the load until the platen gap has closed to 50% of the average test piece size.

Clean the platens thoroughly before the next test piece(single pellet) is tested.

Repeat the procedure on the remaining test pieces.

4. Main technical specifications of testing machine:

No. | Inspection items | Technical specifications |

1 | Max. load | 10KN |

2 | Precision class | Class 1 |

3 | Measuring range of load | 1%-100%FS |

4 | Relative error of indicating value | ±1.0% |

5 | Min reading value of deformation | 0.01mm |

5 | Resolution of test force | 1/300000F.S (with constant resolution within the whole stroke) |

6 | Adjusting range of control rate of load | 0.005%-5%FS/s |

7 | Adjusting range of deformation rate | 0.005-5%FS/s |

8 | Control precision of deformation rate | When rate<0.05%FS/s, the precision is within ±1% of setting value; When rate ≥0.005%FS/s, the precision is within ±0.5% of setting value |

9 | Adjusting range of displacement rate | 0.01-500mm/min |

10 | Control precision of displacement rate | Within 0.2% of setting value |

11 | Effective test span | 360mm |

12 | Effective compression space | 400mm |

13 | Control mode | Computer |

14 | Power supply | 220V, 50Hz, 400W |

15 | Dimension of main machine | 410x660x820mm |

16 | Weight of main machine | 80kg |

How to Select the Right Tensile, Compression, Bending, Shear, Peel, and Tear Testing Machine: Calculation Formulas with Examples

Selecting the appropriate testing machine for tensile, compression, bending, shear, peel, and tear tests requires careful consideration of multiple factors, including the force range, specimen dimensions, test standards, and machine capabilities. Below are the key calculation formulas to help determine the necessary machine specifications, along with examples for better understanding.

1. Tensile Testing Machine Selection

Tensile testing machines measure the maximum tensile strength and elongation of materials.

Key Formula:

Fmax=σmax × A

Where:

Fmax = Maximum required force (N)

σmax = Ultimate tensile strength of the material (MPa)

A = Cross-sectional area of the specimen (mm²)

Example: For a steel specimen with σmax =400MPa and cross-sectional area A =100mm²:

Fmax=400 × 100=40,000N (40kN)

A 50 kN tensile testing machine would be suitable.

2. Compression Testing Machine Selection

Compression tests determine a material's resistance to compressive forces.

Key Formula:

Fmax=σc × A

Where:

Fmax = Maximum required force (N)

σc = Compressive strength of the material (MPa)

A = Cross-sectional area of the specimen (mm²)

Example: For a concrete cube with σc =30MPa and A =1502=22,500mm²:

Fmax=30 × 22,500=675,000N (675kN)

A 1000 kN compression testing machine would be ideal.

3. Bending Testing Machine Selection

Bending tests evaluate the flexural strength of materials.

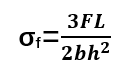

Key Formula for Three-Point Bending:

Where:

σf = Flexural stress (MPa)

F= Applied force (N)

L= Span length (mm)

b= Width of the specimen (mm)

h= Thickness of the specimen (mm)

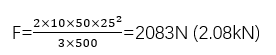

Example: For a wooden beam with L=500mm, b=50mm, h=25mm, and requiring a stress of 10 MPa:

A 5 kN bending tester would be suitable.

4. Shear Testing Machine Selection

Shear tests determine the shear strength of materials.

Key Formula:

Fmax=τ × A

Where:

Fmax = Maximum shear force (N)

τ= Shear strength of the material (MPa)

A = Shear area (mm²)

Example: For an aluminum sheet with τ=90 MPa and A=200mm²:

Fmax=90×200=18,000N(18kN)

A 20 kN shear testing machine is recommended.

5. Peel Testing Machine Selection

Peel tests measure the adhesion strength between bonded materials.

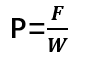

Key Formula:

Where:

P= Peel strength (N/mm)

F= Measured force (N)

W= Width of the specimen (mm)

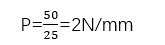

Example: For a tape with F=50N and W=25mm:

A peel testing machine with at least 5 N force capacity is required.

6. Tear Testing Machine Selection

Tear tests determine the resistance of a material to tearing forces.

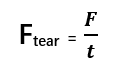

Key Formula:

Where:

Ftear= Tear strength (N/mm)

F= Measured force (N)

t= Thickness of the specimen (mm)

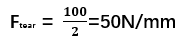

Example: For a rubber sheet with F=100N and t=2mm:

A tear testing machine with 100 N capacity is needed.

When selecting a testing machine, ensure that the maximum force capacity of the machine is at least 1.2 to 1.5 times the calculated force to account for safety margins and unexpected variations. Additionally, consider compliance with relevant test standards (ASTM, ISO, GB, EN, JIS) and machine features such as speed control, data acquisition, and test automation.

By using the above formulas and examples, engineers and manufacturers can accurately determine the appropriate testing machine specifications for their specific material and application requirements.

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- all testing machine and equipment

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

- test fixtures

- torsion tester

- cupping testing machine

- friction and wear tester

Contact Us

- +86-18615632092

- sophie@jnwtbte.com

- +86-18615632092

售前客服

售前客服