MMW-1A universal friction and wear testing machine

The MMW-1A Universal Friction and Wear Testing Machine evaluates the friction and wear performance of lubricants and various materials under a specific contact pressure through sliding, rolling, and combined motion friction forms. Based on customer requirements, it can be equipped with multiple friction pairs, including pin-on-disk (with large and small disks, single and triple pins), four-ball, thrust ring, ball-three-plate, pin-three-plate, simulated cam, and gear configurations, enabling diverse friction and wear tests. Leather friction testing can be achieved using the pin-on-disk friction pair, where the disk fixture holds the leather sample and the pin fixture holds the test specimen. This machine can operate under extremely low or high-speed conditions to assess the friction and wear performance of materials such as leather, lubricants, metals, plastics, sandpaper, coatings, rubber, and ceramics. It is widely applicable in tribology-related fields and meets the needs of industries like petrochemicals, machinery, energy, metallurgy, and aerospace for developing, testing various mid-to-high-end oil and grease products, as well as emerging materials and new processes in friction and wear testing.

2.relative test methods

SH/T 0189 Test Method for Anti-Wear Performance of Lubricating Oil (Four-Ball Method)

SH/T 0204 Test Method for Anti-Wear Properties of Lubricating Grease (Four-Ball Method)

SH/T 0762 Lubricant Friction Coefficient Test Method (Four-Ball Method)

ASTM D5183 Test Method for Measuring the Coefficient of Friction of Lubricating Oils Using a Four-Ball Wear Machine

ASTM G3702 Test Method for Determining the Frictional Properties of Materials Using Thrust Washers

ASTM G99 Test Method for Determining the Frictional Properties of Materials Using a Pin-on-Disk Apparatus

3. specifications

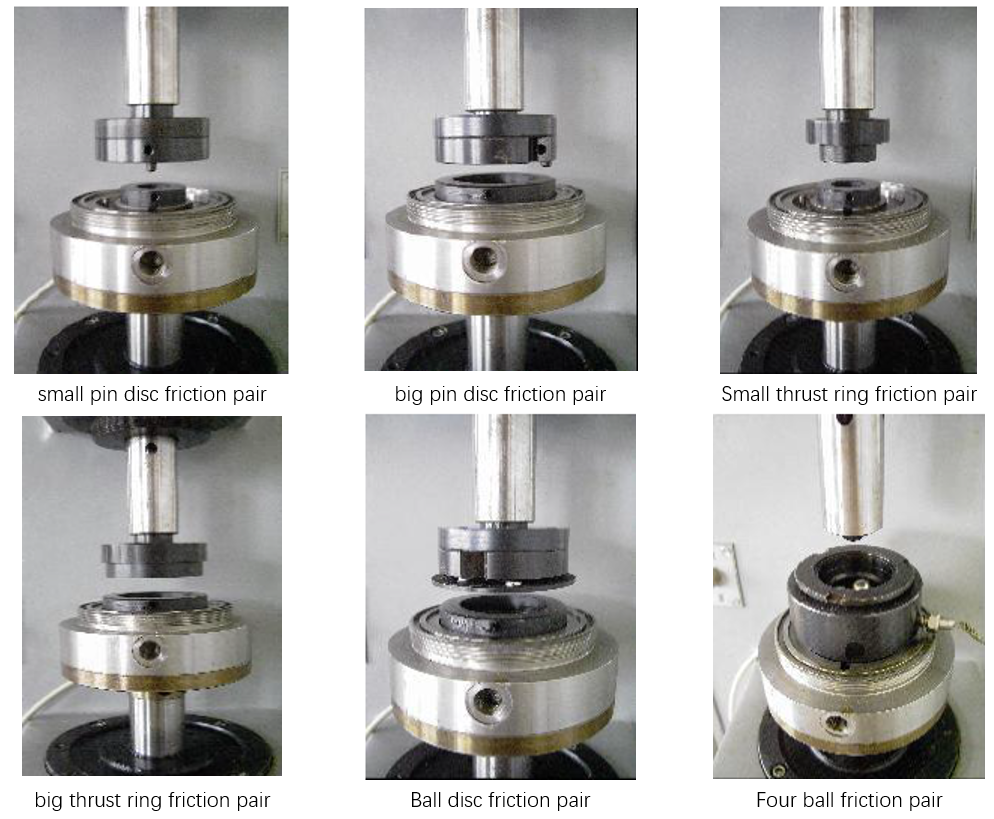

4. Specialized friction pair

The function of the friction pair of the testing machine can be expanded according to customer needs

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- all testing machine and equipment

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

- test fixtures

- torsion tester

- cupping testing machine

- friction and wear tester

Contact Us

- +86-18615632092

- sophie@jnwtbte.com

- +86-18615632092

售前客服

售前客服