WAL-600KN computerized hydraulic horizontal tensile testing machine

1. Applications

Test types: tension test for steel rod, wire rope, steel wire, steel strand, chain or other samples required by client

Application field: construction and building industries, metallurgical industry, transportation industry, energy resources industry, scientific research unit, college and universities, quality inspection center, commodity inspection department, etc.

2. Introductions of the machine

l Adopt frame structure, hydraulic loading, test force is loaded via single rod double acting piston cylinder.

l Double pump structure of hydraulic working stations, one is low pressure pump with large flow for quick feeding of piston, the other one is gear pump with high pressure

l Buffering functions at break for hydraulic station. The hydraulic station will auto release oil pressure in hydraulic system at the time sample breaks to protect the machine.

l Tightening mechanism is used on back grips. At the beginning of the test, the grips will tight test sample with tightening mechanism, especially for long samples like hanging belt, nylon rope, etc, and auto stop when reach set original force value and then start formal tension test. This tightening mechanism can improve the working efficiency for long test sample with long elongation.

l Equip with hydraulic protecting cover, close and open of the protecting cover is hydraulic control, easy and convenient to operate.

l Computer test software display test force and piston displacement in real time and has functions of auto analyze, process and save test result. Printer is equipped for printing required test report.

l High rigid of main loading frame, small deformation during test, adjusting test space for test sample with different length.

l Adopt closed loop control to drive electro-hydraulic servo control system, computer software control multi-grade hydraulic loading. It loads stably and continuously and has functions of force maintaining, auto collecting test data and display test curves.

3. technical specifications

Force capacity | 600KN |

Frame structure | Single rod double acting cylinder frame |

Loading speed | 0.5-50Kn/S |

Operating height for test | 900mm |

Control mode | Computerized electro-hydraulic servo control |

Test type | Tension test in ambient temperature |

Over load protecting | 105% of force capacity |

Accuracy of force indicating | Better than ±1% |

Resolution of force | 1/500000 in whole capacity |

Force measuring range | 2%-100%FS(60-3000KN) |

Accuracy of force control | Better than ±1% |

Accuracy of stress control | Better than ±1% |

Accuracy of displacement control | Better than ±1% |

Resolution of displacement | 0.001mm |

Accuracy of displacement speed | Better than ±0.5% |

Moving speed of piston | 0-200mm/min |

Stroke of piston | 1500mm |

Max. tension length | 10000mm (can be shorter or longer) |

Max. compression space | 1500mm |

Interval for tension space adjusting | 500mm |

Width for tension test(distance between two columns) | 800mm |

Center height for tension test | 600mm |

Motor power | 11KW |

Dimension | 14500x1500x900mm |

How to Select the Right Tensile, Compression, Bending, Shear, Peel, and Tear Testing Machine: Calculation Formulas with Examples

Selecting the appropriate testing machine for tensile, compression, bending, shear, peel, and tear tests requires careful consideration of multiple factors, including the force range, specimen dimensions, test standards, and machine capabilities. Below are the key calculation formulas to help determine the necessary machine specifications, along with examples for better understanding.

1. Tensile Testing Machine Selection

Tensile testing machines measure the maximum tensile strength and elongation of materials.

Key Formula:

Fmax=σmax × A

Where:

Fmax = Maximum required force (N)

σmax = Ultimate tensile strength of the material (MPa)

A = Cross-sectional area of the specimen (mm²)

Example: For a steel specimen with σmax =400MPa and cross-sectional area A =100mm²:

Fmax=400 × 100=40,000N (40kN)

A 50 kN tensile testing machine would be suitable.

2. Compression Testing Machine Selection

Compression tests determine a material's resistance to compressive forces.

Key Formula:

Fmax=σc × A

Where:

Fmax = Maximum required force (N)

σc = Compressive strength of the material (MPa)

A = Cross-sectional area of the specimen (mm²)

Example: For a concrete cube with σc =30MPa and A =1502=22,500mm²:

Fmax=30 × 22,500=675,000N (675kN)

A 1000 kN compression testing machine would be ideal.

3. Bending Testing Machine Selection

Bending tests evaluate the flexural strength of materials.

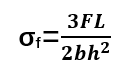

Key Formula for Three-Point Bending:

Where:

σf = Flexural stress (MPa)

F= Applied force (N)

L= Span length (mm)

b= Width of the specimen (mm)

h= Thickness of the specimen (mm)

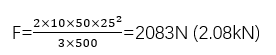

Example: For a wooden beam with L=500mm, b=50mm, h=25mm, and requiring a stress of 10 MPa:

A 5 kN bending tester would be suitable.

4. Shear Testing Machine Selection

Shear tests determine the shear strength of materials.

Key Formula:

Fmax=τ × A

Where:

Fmax = Maximum shear force (N)

τ= Shear strength of the material (MPa)

A = Shear area (mm²)

Example: For an aluminum sheet with τ=90 MPa and A=200mm²:

Fmax=90×200=18,000N(18kN)

A 20 kN shear testing machine is recommended.

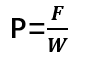

5. Peel Testing Machine Selection

Peel tests measure the adhesion strength between bonded materials.

Key Formula:

Where:

P= Peel strength (N/mm)

F= Measured force (N)

W= Width of the specimen (mm)

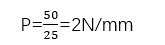

Example: For a tape with F=50N and W=25mm:

A peel testing machine with at least 5 N force capacity is required.

6. Tear Testing Machine Selection

Tear tests determine the resistance of a material to tearing forces.

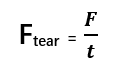

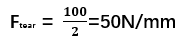

Key Formula:

Where:

Ftear= Tear strength (N/mm)

F= Measured force (N)

t= Thickness of the specimen (mm)

Example: For a rubber sheet with F=100N and t=2mm:

A tear testing machine with 100 N capacity is needed.

When selecting a testing machine, ensure that the maximum force capacity of the machine is at least 1.2 to 1.5 times the calculated force to account for safety margins and unexpected variations. Additionally, consider compliance with relevant test standards (ASTM, ISO, GB, EN, JIS) and machine features such as speed control, data acquisition, and test automation.

By using the above formulas and examples, engineers and manufacturers can accurately determine the appropriate testing machine specifications for their specific material and application requirements.

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- all testing machine and equipment

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

- test fixtures

- torsion tester

- cupping testing machine

- friction and wear tester

Contact Us

- +86-18615632092

- sophie@jnwtbte.com

- +86-18615632092

售前客服

售前客服