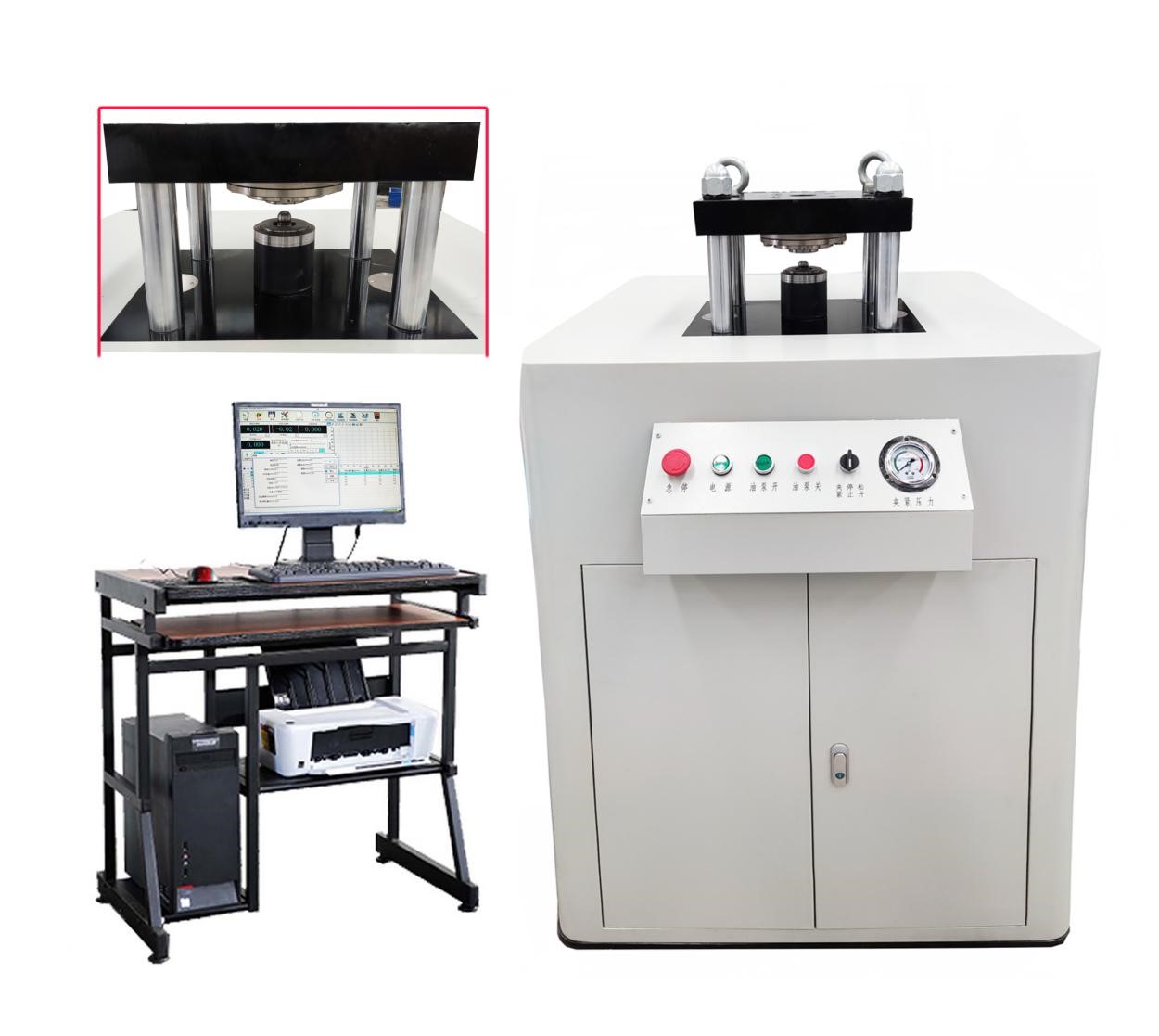

GBW-60 computerized cupping tester

1.Brief introduction

This testing machine has comprehensive functions and performance Meets the current national standards for cupping tests on metal sheets, aluminum and aluminum alloy sheets, and surface coatings of metal sheets,

https://youtube.com/shorts/ClSG75T2POU

2.The reference standards are as follows:

GB/T4156-2007 "Erickson cupping test method for thin sheets and strips of metallic materials"

GB/T24524-2009 Test Method for Hole Expansion of Thin Plates and Strips of Metal Materials,

GB2611-92 General Technical Requirements for Testing Machines

JB/T7408-94 "Technical Conditions for Cup Bulge Testing Machine"

3. Main specifications

3.1. Sheet thickness: 0.01-3mm (high-precision sensor, capable of conducting ultra-thin sheet testing)

3.2. Board width: 90-100mm;

3.3. Punch stroke, 40mm;

3.4. Tighten the piston stroke by 40mm.

3.5. The maximum stamping load is 60kN.

3.6. The maximum clamping load is 10kN.

3.7. Cup protrusion resolution: 0.0025mm

3.8. Cup protrusion test mold specifications:

l Standard punch ball: φ 20 ± 0.05mm

l Standard pad mold aperture: φ 33 ± 0.1mm

l Standard pad mold outer diameter: φ 55 (sample thickness 0.1-2) φ 70 (sample thickness 2-3)

l Standard die aperture: 27 ± 0.05mm (sample thickness 0.1-2) 40 ± 0.05mm (sample thickness 2-3)

l Standard die outer diameter: φ 55 (sample thickness 0.1-2) φ 70 (sample thickness 2-3)

3.9. Special orders can provide non-standard molds. Cup protrusion testing machine that meets international standards such as American and European standards.

3.10. Test speed: between 5mm/min and 20mm/min can be set freely and controlled accurately.

3.11. When a crack appears to penetrate the entire thickness of the specimen, the punch can immediately stop moving.

3.12. Hydraulic oil: N46 hydraulic oil.

3.13. Host dimensions: 800 × 760 × 1500 (mm)

3.14. Power supply AC380V, 50Hz.

3.15. Weight 510Kg.

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- all testing machine and equipment

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

- test fixtures

- torsion tester

- cupping testing machine

- friction and wear tester

Contact Us

- +86-18615632092

- sophie@jnwtbte.com

- +86-18615632092

售前客服

售前客服