GJW-600KN computerized steel strand tensile testing machine

Steel strand tensile testing machine

1. Introduction

The computer control electro-hydraulic servo steel strand universal tensile testing machine adopts advanced electro-hydraulic servo control system, high precision load cell, loading stable, measuring accurately and convenient to operate.

With many control modes such as load/stress control, displacement control, deformation/strain control.

It is mainly to do tensile test for steel strand according to test method GB/T5224, ISO 6934-4 and other similar test method.

2. specification

Item | Spec. |

Max capacity | 600KN |

Measuring range | 1%-100%FS |

Accuracy | 0.5% or 1% |

Load resolution | 1/300000 |

Deformation measuring range | 1-100%FS |

Deformation value precision | 0.5% or 1% |

Stress control speed | 1-45Mpa/s |

Stress control speed | 0.06-30mm/min |

Displacement speed | 1-180mm/min |

Crossbeam adjusting mode | Chain gear transmission |

Tensile space | 700mm |

Compression space | 650mm |

Distance between columns | 500mm |

Piston stroke | 250mm |

Dim. Of loading frame | 800x620x2650mm |

Flat grip | 0-30mm |

Round grip | 13-40mm |

Weight | 2700kg |

How to Select the Right Tensile, Compression, Bending, Shear, Peel, and Tear Testing Machine: Calculation Formulas with Examples

Selecting the appropriate testing machine for tensile, compression, bending, shear, peel, and tear tests requires careful consideration of multiple factors, including the force range, specimen dimensions, test standards, and machine capabilities. Below are the key calculation formulas to help determine the necessary machine specifications, along with examples for better understanding.

1. Tensile Testing Machine Selection

Tensile testing machines measure the maximum tensile strength and elongation of materials.

Key Formula:

Fmax=σmax × A

Where:

Fmax = Maximum required force (N)

σmax = Ultimate tensile strength of the material (MPa)

A = Cross-sectional area of the specimen (mm²)

Example: For a steel specimen with σmax =400MPa and cross-sectional area A =100mm²:

Fmax=400 × 100=40,000N (40kN)

A 50 kN tensile testing machine would be suitable.

2. Compression Testing Machine Selection

Compression tests determine a material's resistance to compressive forces.

Key Formula:

Fmax=σc × A

Where:

Fmax = Maximum required force (N)

σc = Compressive strength of the material (MPa)

A = Cross-sectional area of the specimen (mm²)

Example: For a concrete cube with σc =30MPa and A =1502=22,500mm²:

Fmax=30 × 22,500=675,000N (675kN)

A 1000 kN compression testing machine would be ideal.

3. Bending Testing Machine Selection

Bending tests evaluate the flexural strength of materials.

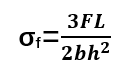

Key Formula for Three-Point Bending:

Where:

σf = Flexural stress (MPa)

F= Applied force (N)

L= Span length (mm)

b= Width of the specimen (mm)

h= Thickness of the specimen (mm)

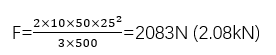

Example: For a wooden beam with L=500mm, b=50mm, h=25mm, and requiring a stress of 10 MPa:

A 5 kN bending tester would be suitable.

4. Shear Testing Machine Selection

Shear tests determine the shear strength of materials.

Key Formula:

Fmax=τ × A

Where:

Fmax = Maximum shear force (N)

τ= Shear strength of the material (MPa)

A = Shear area (mm²)

Example: For an aluminum sheet with τ=90 MPa and A=200mm²:

Fmax=90×200=18,000N(18kN)

A 20 kN shear testing machine is recommended.

5. Peel Testing Machine Selection

Peel tests measure the adhesion strength between bonded materials.

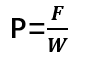

Key Formula:

Where:

P= Peel strength (N/mm)

F= Measured force (N)

W= Width of the specimen (mm)

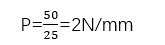

Example: For a tape with F=50N and W=25mm:

A peel testing machine with at least 5 N force capacity is required.

6. Tear Testing Machine Selection

Tear tests determine the resistance of a material to tearing forces.

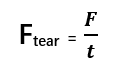

Key Formula:

Where:

Ftear= Tear strength (N/mm)

F= Measured force (N)

t= Thickness of the specimen (mm)

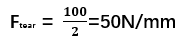

Example: For a rubber sheet with F=100N and t=2mm:

A tear testing machine with 100 N capacity is needed.

When selecting a testing machine, ensure that the maximum force capacity of the machine is at least 1.2 to 1.5 times the calculated force to account for safety margins and unexpected variations. Additionally, consider compliance with relevant test standards (ASTM, ISO, GB, EN, JIS) and machine features such as speed control, data acquisition, and test automation.

By using the above formulas and examples, engineers and manufacturers can accurately determine the appropriate testing machine specifications for their specific material and application requirements.

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- all testing machine and equipment

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

- test fixtures

- torsion tester

- cupping testing machine

- friction and wear tester

Contact Us

- +86-18615632092

- sophie@jnwtbte.com

- +86-18615632092

售前客服

售前客服