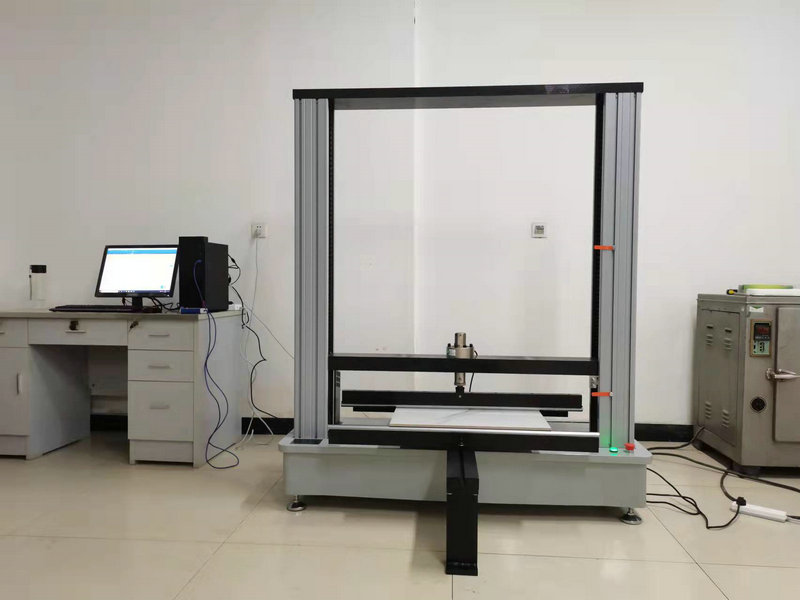

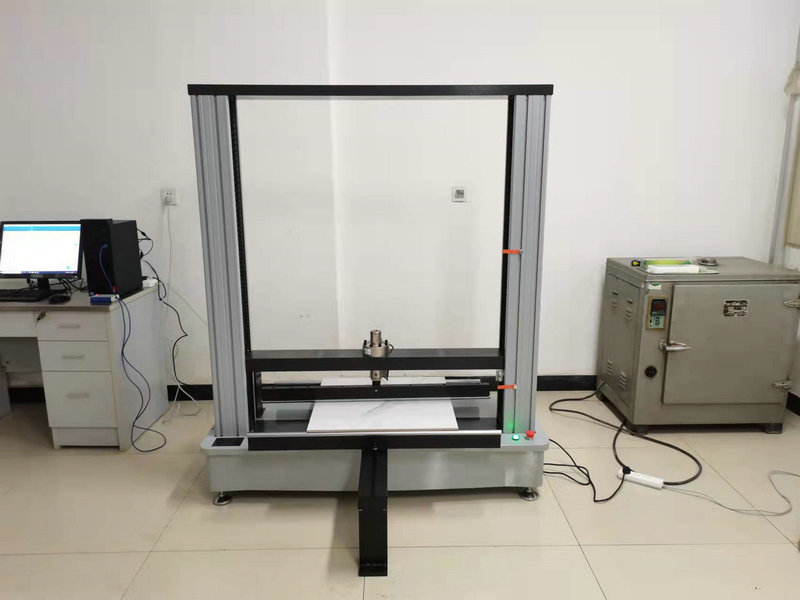

WDW-20KN computerized ceramic tiles flexural testing machine

WDW-20KN microcomputer-controlled ceramic tile flexural testing machine is used for three-point and four-point flexural testing of tiles and glass, and can detect the flexural strength of tiles or glass and similar plate samples.

1. Product introduction

WDW-20KN microcomputer-controlled ceramic tile flexural testing machine is used for three-point and four-point flexural testing of tiles and glass, and can detect the flexural strength of tiles or glass and similar plate samples. WDW-20KN microcomputer-controlled ceramic tile bending testing machine system adopts microcomputer closed-loop control, has wide and accurate loading speed and force measurement range, and has high precision and sensitivity for the measurement and control of load and displacement. The design of the main body of the testing machine has the characteristics of beautiful appearance, convenient operation, stable and reliable performance, no pollution, low noise and high efficiency. The design of the auxiliary equipment matches the main engine, and the structure is wedge-type translation type, manual rotation clamping, and the sample is not subject to additional force. The clamping is convenient, reliable and non-slip.

This machine is suitable for testing the mechanical properties of various metals, non-metals and composite materials, and fully meets the requirements of relevant national standards. This machine is widely used in material inspection and analysis of building materials, aerospace, machinery manufacturing, wire and cable, rubber and plastics, automobile manufacturing, shock absorption systems and other industries. Ideal test equipment for other departments.

2.specifications

No | Item | Specification |

1 | Force capacity | 20KN and lower |

2 | Measuring range | 1%-100%FS |

3 | Accuracy of force value | Less than ±1% of set value |

4 | Precision of displacement | 0.01mm |

5 | Accuracy of displacement value | ±1% |

6 | Deformation measuring range | 0.4%-100%FS |

7 | Accuracy of deformation measuring | ±0.5% |

8 | Resolution of deformation | 0.01mm |

9 | Force speed range | 0.005-5%FS/S |

10 | Accuracy of force speed | Less than ±1% of set value |

11 | Deformation speed range | 0.02-5%FS/S |

12 | Accuracy of deformation speed control | When set value is less than 0.05%FS,error is less than ±2.0% of set value When set value is more than 0.05%FS,error is less than ±0.5% of set value |

13 | Displacement speed range | 0.001-500mm/min |

14 | Accuracy of displacement speed | When speed is less than 0.01mm/min,error is less than ±1.0% of set value When set value is more than 0.01mm/min,error is less than ±0.2% of set value |

15 | Range of constant force, constant deformation, constant displacement control | 0.5%~100%FS |

16 | Accuracy of constant force, constant deformation, constant displacement control | When set value is less than 10%FS,error is less than ±1.0% of set value When set value is more than 10%FS,error is less than ±0.1% of set value |

17 | Accuracy of deformation speed | When set value is less than 0.05%FS,error is less than ±2.0% of set value When set value is more than 0.05%FS,error is less than ±0.5% of set value |

18 | Tension space | 700mm |

20 | Voltage | Single phase,220V±10%,50Hz(110V) |

21 | Motor power | 0.75KW |

22 | Dimension | 750x480x1700mm |

23 | Weight | 280kg |

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- utm

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服