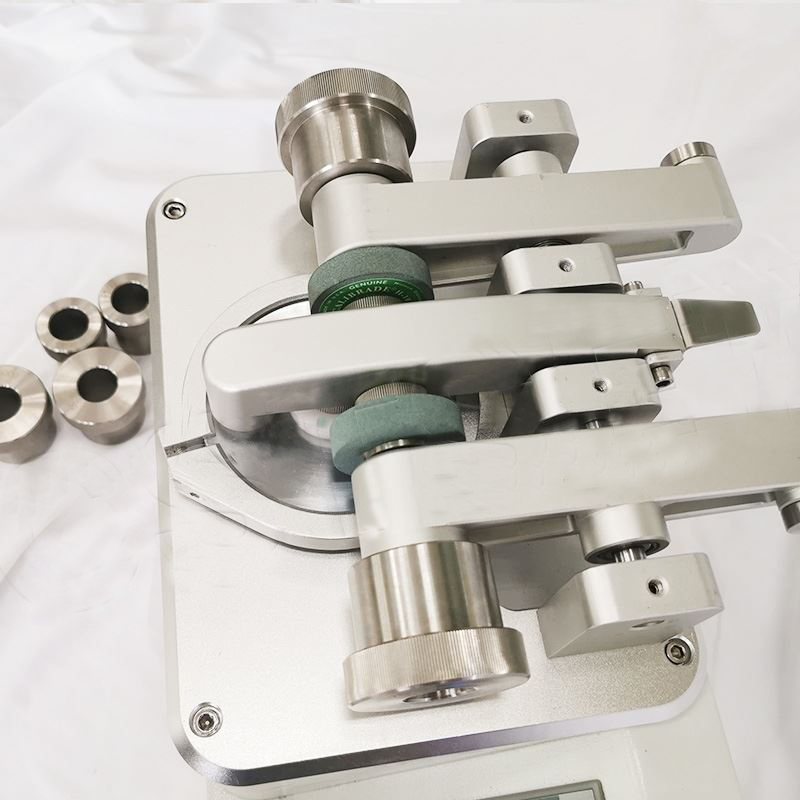

WT-6054 TABER abrasion resistance testing machine

WT-6054 TABER abrasion resistance testing machine

WT-6054 TABER abrasion resistance testing machine

![]() WT-6054 TABER abrasion resistance testing machine.pdf

WT-6054 TABER abrasion resistance testing machine.pdf

1. Introductions

The TABER abrasion resistance testing machine it to measure and determine the anti-abrasion resistance of rubber, flooring, tiles, leather, and PU materials.

2. Relative test methods

QB/T 2726leather --- physical and mechanical tests --- determination of abrasion resistance

GB/T 16799 furniture leather

DIN 53109 testing of paper and board--- determination of abrasion by the abrasion wheel method

DIN 52347 testing of glass and plastics: abrasion test: method using abrasion wheels and measurement of scattered light

ASTM D1044 standard test method for resistance of transparent plastics to surface abrasion

QB/T 2703 automotive upholstery leather

ASTM D3884 standard guide for abrasion resistance of textile fabrics (rotary platform, double-head method

ISO 5470-1 rubber- or plastics-coated fabrics – determination of abrasion resistance – part 1: taber abrader

TAPPI T476 abrasion loss of paper and paperboard (taber-type method)

3.specifications

No. | Item | Spec. |

1 | Test speed | 0-72r/min adjustable |

2 | Equipped weights | 250g,500g,750g |

3 | Test specimen size | Outside diameter 106mm Inside diameter 8mm |

4 | Test station | 1 test station |

5 | Counting range | 0-9999999 |

6 | Protecting cover | transparent cover with self-locking function |

7 | Sample fixture device | One click jog, automatically resets |

8 | Dimension | 530x320x310mm |

9 | Weight | 28kg |

10 | Voltage | AC220V,10A |

4.features

l Surface treatment of the body: Using DuPont powder from the United States and electrostatic spray painting technology, it is cured at high temperature of 200 ℃ to ensure long-lasting color fastness.

l LED-SLD806 integrated display control box, menu style operation mode;

l The position can be adjusted by jogging, and the test speed can be adjusted;

l The mechanical components are composed of non corrosive structural aluminum and stainless steel materials;

l Precision drive motor, smooth operation, low noise;

l Equipped with counting and timing self stop functions, the test can be automatically stopped by setting the test value;

l High precision bearings are selected for smooth and stable rotation, with a long service life;

l One click fully automatic testing, simple and convenient operation;

l New vertical structure design, convenient sample installation;

l Open and close protective cover, which can protect the operator's safety and has the function of stop immediately while opening the cover

l Refer to following Table for the configuration of grinding wheels:

Test sample | Coating | Floor tile | Wood | Rubber& plastic | leather |

Abrasion shaft | CS10 CS17 | CS17 | S32 S33 | CS17 H-18 H22 | H-18 |

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- utm

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服