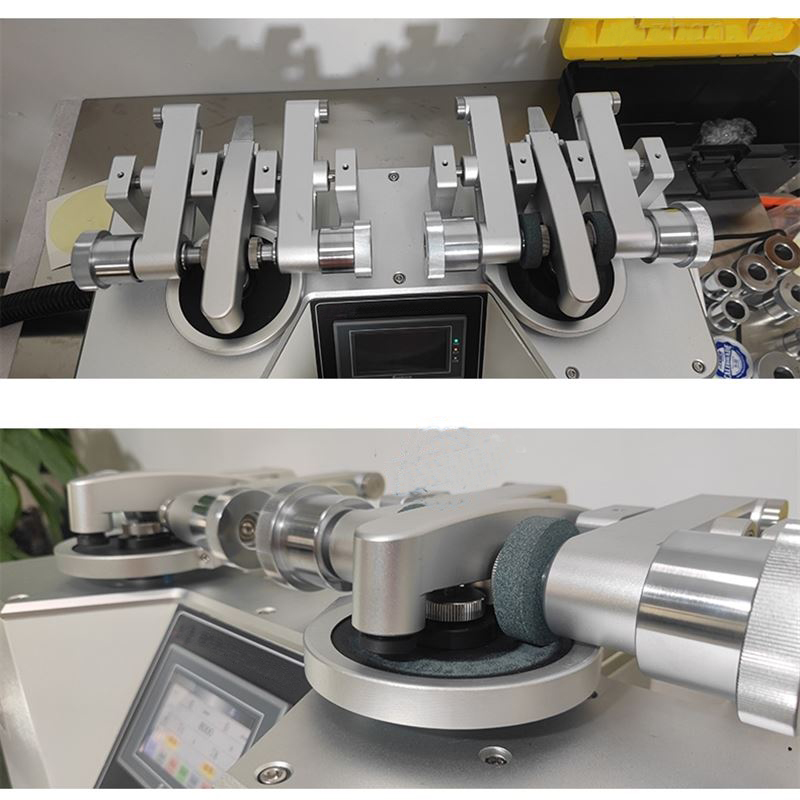

WT-6054B 2 stations TABER abrasion tester

WT-6054B 2 stations TABER abrasion tester

WT-6054B 2 stations TABER abrasion tester

![]() WT-6054B 2 stations TABER abrasion tester.pdf

WT-6054B 2 stations TABER abrasion tester.pdf

1. Introductions

The dual station TABER wear tester is used to test the wear resistance of materials such as textiles, paper, coatings, synthetic boards, leather, floor tiles, glass, wood, metal, rubber, etc.

2. Relative test methods

QB/T 2726leather --- physical and mechanical tests --- determination of abrasion resistance

GB/T 16799 furniture leather

ISO 16131 upholstery leather characteristics --- leather for furniture

DIN 53109 testing of paper and board--- determination of abrasion by the abrasion wheel method

DIN 52347 testing of glass and plastics: abrasion test: method using abrasion wheels and measurement of scattered light

ASTM D1044 standard test method for resistance of transparent plastics to surface abrasion

QB/T 2703 automotive upholstery leather

ASTM D3884 standard guide for abrasion resistance of textile fabrics (rotary platform, double-head method

ISO 5470-1 rubber- or plastics-coated fabrics – determination of abrasion resistance – part 1: taber abrader

TAPPI T476 abrasion loss of paper and paperboard (taber-type method)

SATRA TM163 abrasion resistance – taber method

GB/T 18102 laminated floor coverings

GB/T 15036.2 solid wood flooring—part 2: Examination methods

3.specifications

No. | Item | Spec. |

1 | Equipped weights | 250g,500g,750g |

2 | Test load | 250g,500g,1000g |

3 | Test station | 2 test stations |

4 | Test speed | 0-72r/min adjustable |

5 | Counting range | 0-9999999 |

6 | Distance between test specimen and nozzle | 1-2mm |

7 | Test specimen size | Outside diameter 106mm Inside diameter 8mm |

8 | Distance between center of abrasion wheels | 19.1±0.1mm |

9 | Dimension | 530x320x310mm |

10 | Weight | 28kg |

4.features

l Surface treatment of the body: Using DuPont powder from the United States and electrostatic spray painting technology, it is cured at high temperature of 200 ℃ to ensure long-lasting color fastness.

l LED-SLD806 integrated display control box, menu style operation mode;

l The position can be adjusted by jogging, and the test speed can be adjusted;

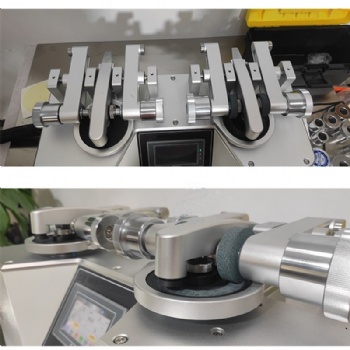

l The mechanical components are composed of non corrosive structural aluminum and stainless steel materials;

l Precision drive motor, smooth operation, low noise;

l Equipped with counting and timing self stop functions, the test can be automatically stopped by setting the test value;

l High precision bearings are selected for smooth and stable rotation, with a long service life;

l One click fully automatic testing, simple and convenient operation;

l New vertical structure design, convenient sample installation;

l Refer to following Table for the configuration of grinding wheels:

Test sample | Coating | Floor tile | Wood | Rubber& plastic | leather |

Abrasion shaft | CS10 CS17 | CS17 | S32 S33 | CS17 H-18 H22 | H-18 |

Categories

- electronic universal testing machine

- hydraulic universal testing machine

- impact testing machine

- compression testing machine

- horizontal tensile testing machine

- manhole cover testing machine

- pellet compression testing machine

- material testing machine

- steel strand tensile testing machine

- rubber testing equipment

- plastic testing equipment

- load cell

- Böhme abrasion tester

- utm

- ceramic tiles testing equipment

- asphalt mixture testing equipment

- footwear testing machine

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服