News

Introductions of drum peel test

Introductions of drum peel test

1. Principle

The peel strength of the panel-to-core bond was determined by peeling the panel from the sandwich structure with a flanged cylinder. One end of the panel is connected to the cylinder body, the other end is connected to the clamp, the flange is connected to the middle carrier tape, and when the loading tape is stretched, the cylinder body rolls upwards, so that the panel is peeled off from the sandwich structure. The loading belt on the flange is relative to the panel on the barrel at a certain distance, and the peel strength of the sandwich structure is actually the peeling resistance torque per unit width of the separation of the panel and the core.

2. Test environment

Temperature: (23±2)℃

Relative humidity: (50±10)%

3. Test method

GB/T 1457 Sandwich Structure Drum Peeling Strength Tester

GB/T 1446 General test methods for the properties of fibre-reinforced plastics fibre-reinforced plastics composites---the generals for determination of properties

ASTM D1781 Standard Test Method for Adhesive Roller Peel

4. Sample

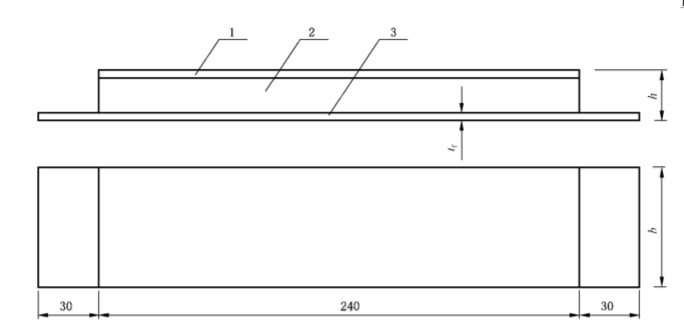

The shape of the sample is as shown in the figure below

Note:

1.non-peeling panel

2.core

3.peeling panel

t:panel thickness

h:specimen thickness

b:specimen width

For continuous cores such as foam, balsa, etc., the specimen width is 60mm

For honeycomb, corrugated and other lattice-shaped cores, the width of the sample is 60mm. When the side length of the lattice is greater than 8mm and the wave distance is greater than 20mm, the width of the sample is 80mm.

5. Test equipment and fixtures

5.1 Test equipment

The electronic tensile testing machine, as shown in the figure below, is a microcomputer-controlled electronic tensile testing machine, and a digital display electronic tensile testing machine can also be used. The precision of the testing machine is grade 1 or 0.5, and the test speed range is 0.1-500mm/min, which can be adjusted freely. Selects the appropriate range according to the peeling force.

5.2 Test fixture

The drum peeling test fixture is as shown in the figure below. The diameter of the drum is 100mm±0.1mm, and the diameter of the drum flange is 125±0.1mm; the loading belt is a flexible steel belt or cable; the drum is made of aluminum alloy material, and the mass does not exceed 1.5kg.

6. Test procedure

6.1 Prepare the specified number of samples and measure the thickness and width of the samples

6.2 Open the test machine and test software, select the appropriate test method, create a new test, input test time, test conditions, test person, sample size, etc.

6.3 Load the prepared specimen into the roller peel tension grip. And the sample and fixture are installed on the testing machine. When loading samples, the test space can be adjusted through software or manual control box.

6.4 Clear each value to zero on the test software. The test speed is set between 20-30mm/min, and then click to start the test.

6.5 When the specified test end conditions are reached, either stop the test manually or set the testing machine to automatically stop the test

6.6 The test software automatically records the force value, displacement and other parameters, and can print the test report with the test curve. The test results are automatically saved at the end of the test and can be recalled and viewed at any time.

We specializes in the production and sales of electronic and hydraulic universal testing machine,electronic and hydraulic tensile testing machine, bending testing machine, horizontal tensile testing machine, impact Testing machine, concrete cement compression testing machine, compressive and flexural integrated testing machine, pellet compression testing machine, manhole cover compression testing machine, tensile stress relaxation testing machine, etc. Welcome your calling or visit

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服