News

Peeling tensile test of plastic composite film composite bag

Peeling tensile test of plastic composite film composite bag

1. Test principle

The samples with a certain width are subjected to T-type peeling at the set speed, and the average peeling force of the composite layer and the substrate is tested.

2. Test equipment

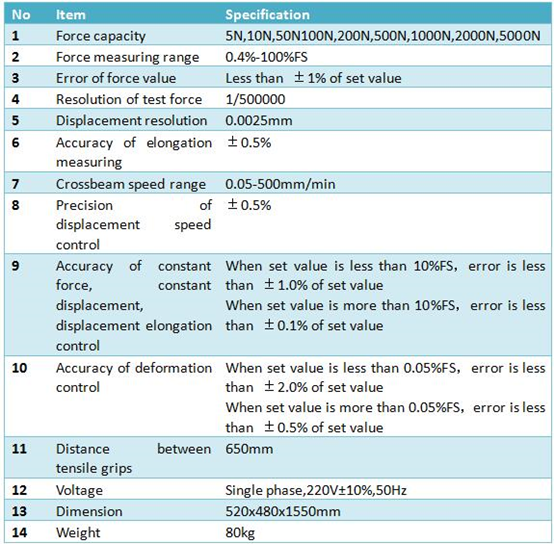

The electronic tensile testing machine is shown in Figure 1 below, and the technical parameters of the testing machine are shown in Table 1 below.

Figure 1: electronic tensile testing machine

Table 1: specification of electronic tensile testing machine

3. Specimen for peeling tensile test

Sample preparation:

Use a suitable tool to remove 50 mm from both ends of the sample width direction, and evenly cut 5 longitudinal samples and 5 horizontal samples along the sample width direction. The composite direction is vertical.

Sample size:

Composite film sample, width 15±0.1mm, length 200mm

Artificial leather, woven composite bag sample, width 30±0.2mm, length 150mm

4. Test environment

Test temperature: 23±2℃

Relative humidity: 45%-55%

The sample needs to be placed in the above test environment for more than 4 hours

5. Test procedure

5.1 Connect the circuits of all parts of the testing machine. Turn on the computer and test software, turn on the switch of the testing machine, and energize the testing machine.

5.2 Strip the composite layer and the base material layer for 50mm in advance along the length of the sample, paying attention that the stripped part should not have obvious damage.

5.3 Clamp one end of the peeled part firmly on the upper or lower clamp of the electronic tensile testing machine.

5.4 Adjust the moving beam of the electronic tensile testing machine, so that the position of the moving beam is moved to the other end of the peeled part of the sample that can be clamped by another fixture of the electronic tensile testing machine. Hold the sample firmly.

5.5 Select the corresponding test method on the test software of the computer, and create a new test. Enter the sample size, test personnel, and select the test speed from the test speed range of 0.01mm/min-500mm/min, such as 200mm/min or 300mm/min.

5.6 Click start test on the test software, the electronic tensile testing machine starts to load the sample, the software collects the test force, and displays the test force, test time, test curve, etc.

5.7 At the end of the test, the test software automatically saves the test results

5.8 Repeat the above steps until 5 tests are completed. Calculate the average.

6. The peeling force requirements of composite film and composite bag are as follows in Table 2

Unit:N/15mm | |||

Ordinary grade | Boiled grade | Semi-high temperature cooking grade | High temperature cooking grade |

≥0.6 | ≥2.0 | ≥3.5 | ≥4.5 |

We specializes in the production and sales of electronic and hydraulic universal testing machine,electronic and hydraulic tensile testing machine, bending testing machine, horizontal tensile testing machine, impact Testing machine, concrete cement compression testing machine, compressive and flexural integrated testing machine, pellet compression testing machine, manhole cover compression testing machine, tensile stress relaxation testing machine, etc. Welcome your calling or visit

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服