News

Introduction to compressive strength test of building thermal insulation mortar GB5486

Introduction to compressive strength test of building thermal insulation mortar GB5486

Building thermal insulation mortar refers to a dry mix mixture made of expanded perlite or expanded vermiculite and cementitious materials and mixed with other functional components for thermal insulation of building walls. For type I building insulation mortar, the compressive strength should be greater than or equal to 0.2Mpa; for type II building insulation mortar, the compressive strength should be greater than or equal to 0.4Mpa. The following are some test steps for testing the compressive strength of building insulation materials using an electronic compression testing machine.

1. Compressive strength sample

Number of samples: randomly select 4 samples

Plate or block sample size: the size of the test pressure surface is 100mm x 100mm, and the thickness of the sample is the thickness of the product

Sampling of plate-shaped or block-shaped samples: When sampling, the plate or block is cut from the center position at a distance of 5mm from the edges of the two diagonals in any diagonal direction.

Sampling of curved plate and tube shell samples: When taking the pieces, make a test piece with a pressure surface size of 100mm x 100mm. If the test piece of 100mm x 100mm cannot be made, the test piece with the minimum pressure surface size of 50mm x 50mm can be made, and the thickness of the test piece shall not be less than 25mm. If the samples of these two sizes cannot be obtained, a flat plate of the same thickness made of the same material and the same process can be used instead.

2. Introduction of compressive strength test steps

2.1 Sample drying: Put the mortar sample in a drying box to dry to constant quality, and then move it to a desiccator to cool to room temperature.

2.2 Measurement: Use a steel ruler or Vernier caliper to measure the length and width of the upper and lower compression surfaces of the sample at a distance of 10mm from the edge, and measure the thickness of the sample in the middle of the two corresponding surfaces. Length and thickness are the average of four measurements, respectively, and thickness is the arithmetic mean of two measurements.

2.3 Sample treatment: For foam glass thermal insulation products, use a paintbrush or scraper to evenly coat the emulsified asphalt or melted asphalt on the upper and lower pressure surfaces of the sample, and flatten the cells. Cut a piece of 100x100mm tar paper to cover the coating and let it dry in a desiccator for at least 24 hours.

2.4 New test: connect the test machine and power on. Open the test software, select an appropriate displacement speed, and pre-run the test machine for a few minutes. Select the test method or edit the test method in the test software, then click the left mouse button on the data panel to create a new test, enter the test number, test personnel, sample size and other parameters in the new data panel that pops up, and press Enter save.

2.5 Placing the sample: Place the processed sample on the lower platen of the testing machine, and adjust the position of the sample according to the ring line on the platen so that the center of the platen coincides with the center of the sample. Adjust the position of the upper platen through the test remote control box so that the upper platen surface is as close as possible to the upper surface of the sample.

2.6 Carry out compressive strength test: select the test speed on the test software, and click to start the test. The test software automatically displays the test force, test time, displacement, test curve, etc.

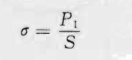

2.7 End of the test: Through the test method selected or edited in 2.4, the test software can record the compression deformation value of the sample when it is damaged or the force value of the sample when the compression deformation is 5% as the failure load, and according to the following formula Calculate compressive strength.

where:

σ------The compressive strength of the sample, the unit is Mpa

P1------ failure load, the unit is N

S ------ the compression area of the sample, the unit is mm2

2.8 Storage and output of test results: After the test is over, the test software automatically saves the test results. Click the print button on the data panel to print a test report with test curves and test data. Test results can be viewed and compared at any time.

2.9 Repeat the above steps until the test of 4 specimens is completed, and then calculate the arithmetic mean of the 4 compressive strengths.

3. Introduction of insulation materials compressive strength testing machine

3.1 Product picture

3.2 Technical parameters of insulation materials compressive strength testing machine

No | Item | Specification |

1 | Force capacity | 20KN |

2 | Measuring range | 1%-100%FS |

3 | Accuracy of force value | Less than ±1% of set value |

4 | Precision of displacement | 0.01mm |

5 | Accuracy of displacement value | ±1% |

6 | Deformation measuring range | 0.4%-100%FS |

7 | Accuracy of deformation measuring | ±0.5% |

8 | Resolution of deformation | 0.01mm |

9 | Force speed range | 0.005-5%FS/S |

10 | Accuracy of force speed | Less than ±1% of set value |

11 | Deformation speed range | 0.02-5%FS/S |

12 | Accuracy of deformation speed control | value is <0.05%FS,error is <±2.0% of set value value is ≥ 0.05%FS,error is <±0.5% of set value |

13 | Displacement speed range | 0.001-500mm/min |

14 | Accuracy of displacement speed | speed is < 0.01mm/min,error is < ±1.0% of set value value is ≥ 0.01mm/min,error is < ±0.2% of set value |

15 | Range of constant force, constant deformation, constant displacement control | 0.5%~100%FS |

16 | Accuracy of constant force, constant deformation, constant displacement control | value is < 10%FS,error is < ±1.0% of set value value is ≥ 10%FS,error is< ±0.1% of set value |

17 | Accuracy of deformation speed | value is < 0.05%FS,error is < ±2.0% of set value value is ≥ 0.05%FS,error is < ±0.5% of set value |

18 | Tension space | 700mm |

20 | Voltage | Single phase,220V±10%,50Hz |

21 | Motor power | 0.75KW |

22 | Dimension | 750x480x1700mm |

23 | Weight | 280kg |

4. Test methods related to compressive strength of insulation materials

GB/T 20473 dry-mixed thermal insulating composition for building

GB/T 5846 test methods for inorganic rigid thermal insulation

We specializes in the production and sales of electronic and hydraulic universal testing machine,electronic and hydraulic tensile testing machine, bending testing machine, horizontal tensile testing machine, impact Testing machine, concrete cement compression testing machine, compressive and flexural integrated testing machine, pellet compression testing machine, manhole cover compression testing machine, tensile stress relaxation testing machine, etc. Welcome your calling or visit

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服