News

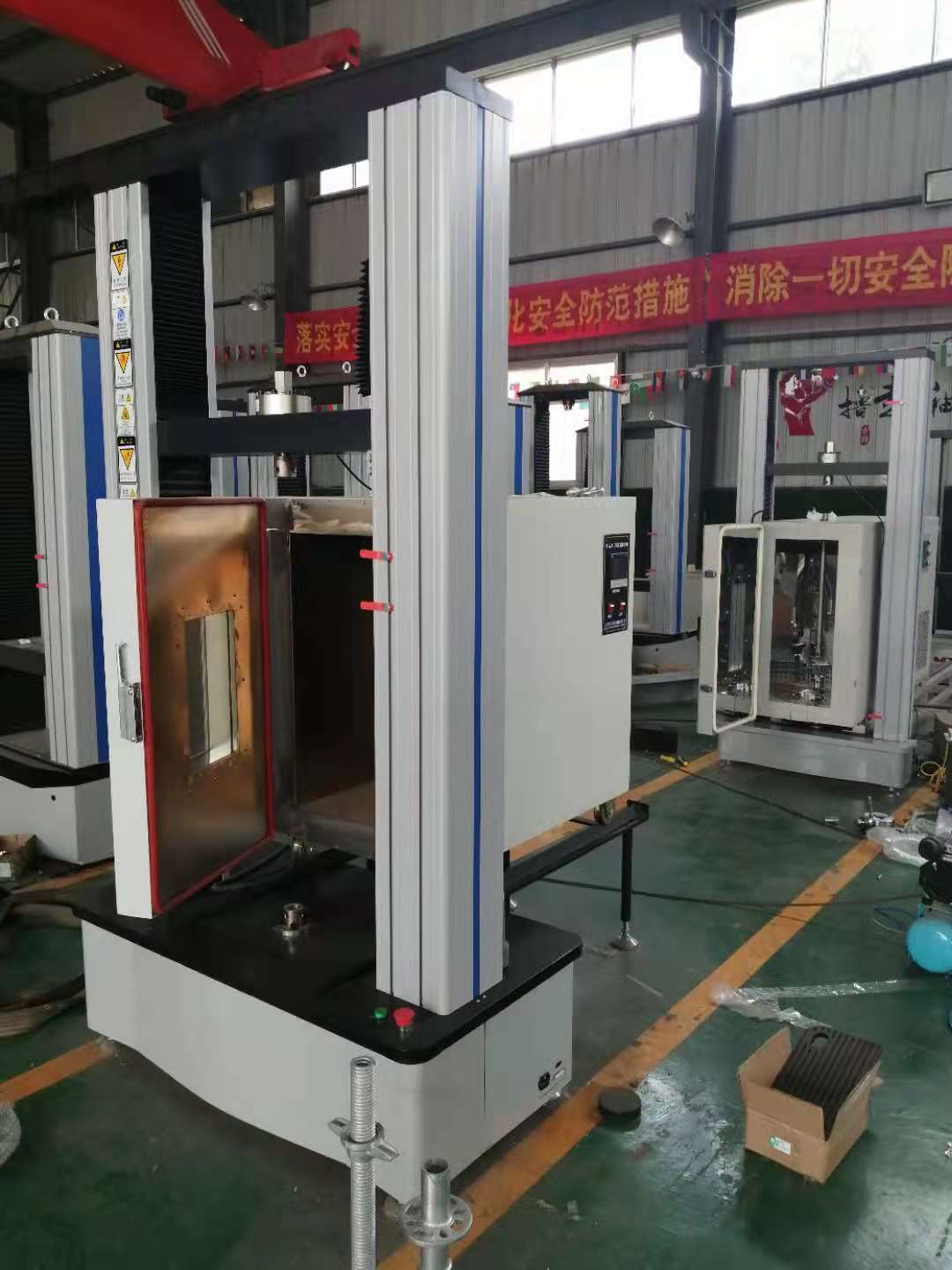

use of high and low temperature universal tensile testing machine

use of high and low temperature universal tensile testing machine

1. Structural requirements of the high and low temperature box of universal tensile testing machine

The inner wall of the high and low temperature box used with the tensile testing machine should be made of heat-resistant materials that are not easy to oxidize and have a certain mechanical strength; the door of the high and low temperature box has good sealing performance, and the sealing material has good resistance to high temperature aging and low temperature hardening. There is no pollution source that affects the test around the high and low temperature universal tensile testing machine. The thermal insulation material used in the high and low temperature test chamber must be thick enough to ensure the temperature of the accessible parts outside the test chamber, and the heat and cold energy of the heating and cooling parts cannot be directly radiated on the sample.

2. Operation of high and low temperature tensile testing machine

1) It is strictly forbidden to use the material testing machine for overloading and over speeding.

2) It is strictly forbidden for hard objects to collide with the lifting screw, and lubricating oil on time.

3) Before using the high and low temperature tensile testing machine, attention should be paid to check the tightening condition of the specimen clamped by the fixture.

4) When lifting and lowering the clamp of the material testing machine, the action should be stable to avoid collision, and the tightness of the clamp should be checked frequently.

5) When opening the fixture of the material testing machine to clamp the sample, pay attention to the clamping distance of the sample, not too much or too little.

6) When replacing the fixture of the high and low temperature tensile testing machine, attention should be paid to cooperation to prevent injury.

7) Before printing the parameters, check whether the printer has paper and replenish it in time.

8) After the operation is completed, the material testing machine should be closed according to the program requirements, and it is strictly forbidden to directly cut off the power supply.

9) Strictly implement the annual inspection system, and regularly identify and certify the parameters of the high and low temperature tensile testing machine by the national metrology and appraisal agency.

3. Precautions for operation of high and low temperature universal tensile testing machine,

1. It is forbidden to heat or test explosive, flammable and highly corrosive substances. Otherwise, unnecessary losses will be caused, or the machine cannot test it.

2. The placement of the sample cannot affect the air circulation of the high and low temperature test chamber, otherwise it will affect the performance of the machine.

3. When using, the door should be closed and closed tightly, otherwise the temperature and humidity will leak out, which will not meet the test requirements.

4. Designate personnel to operate the machine to avoid premature damage to the machine.

5. The high and low temperature tensile testing machine is equipped with a test hole on the left side, which can be used when connecting to the test circuit in the box

6. If you want to observe the changes in the box during the test, you can turn on the [LIGHT] switch of the light in the box, and observe the changes of the samples in the box through the window.

7. If the high and low temperature tensile testing machine is operating below 0°C, try to avoid opening the box door, because at low temperature, opening the box door will easily cause ice sealing in the internal evaporator and other parts, especially the lower the temperature. , the more serious the situation is, if it must be opened, the time should be shortened as much as possible.

8. When the low temperature operation is completed, be sure to set the temperature condition to 60°C and perform drying treatment for about half an hour before opening the box door, so as not to affect the measurement time of the next working condition or the freezing phenomenon of the evaporator or the damage to the test object. (If there is no actual drying treatment at 60°C, the machine malfunctions, although it is within the warranty period, it is also a human negligence, and our company will not provide free service)

We specializes in the production and sales of electronic and hydraulic universal testing machine,electronic and hydraulic tensile testing machine, bending testing machine, horizontal tensile testing machine, impact Testing machine, concrete cement compression testing machine, compressive and flexural integrated testing machine, pellet compression testing machine, manhole cover compression testing machine, tensile stress relaxation testing machine, etc. Welcome your calling or visit

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服