News

flexural strength test of light weight thermally strengthened glass

flexural strength test of light weight thermally strengthened glass

1. Reference test method

GB/T 34328 light weight thermally strengthened glass

2. Test conditions

Ambient temperature: 23±5℃, during the test, the fluctuation of ambient temperature should not be greater than 1℃

Relative humidity of test environment: 40%-70%

3. Specimen for flexural strength test of tempered glass

Number of samples: at least 10 pieces

Sample length: 1100mm±5mm

Specimen width: 360 mm±5mm

Handling of Specimens: When preparing specimens, the cutting edge requires the same surface of the specimen. No handling or processing shall be performed on the specimen within 24 hours before the start of the test. 24 hours before the test, the protective film on the sample should be removed. The samples are to be placed under the specified test conditions for at least 4 hours.

4. Tempered glass bending strength test device

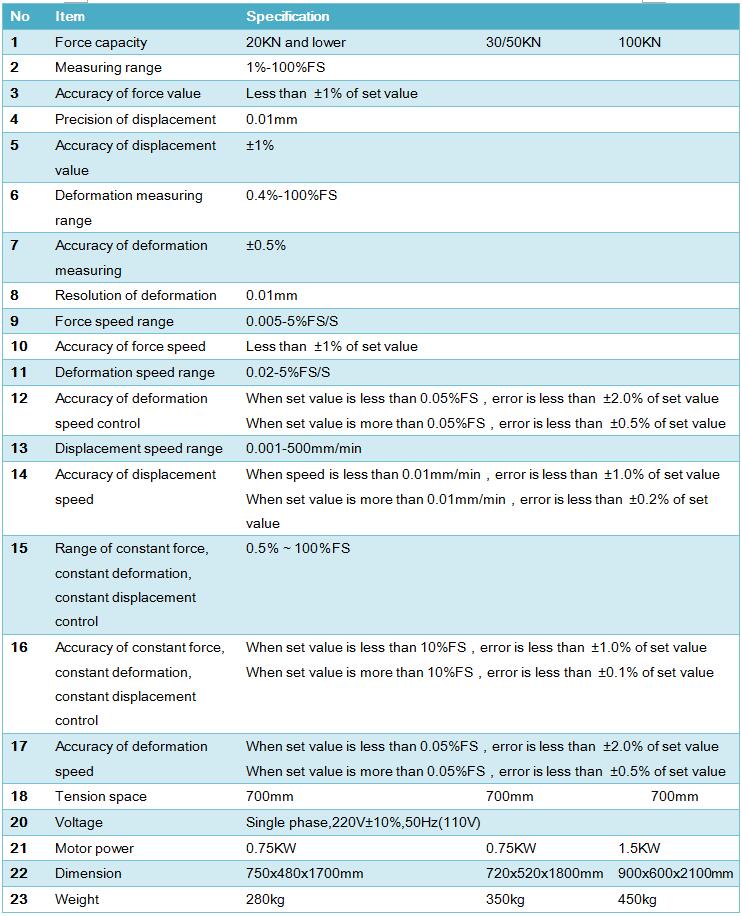

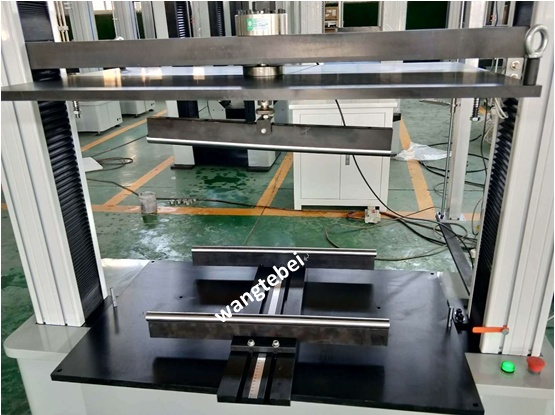

4.1 Electronic material testing machine, the reference photo of the testing machine is shown in Figure 1. Electronic materials testing machines may load the specimen continuously and uniformly. The testing machine software can automatically collect and display the test force, test time, test curve, displacement, deformation, etc. during the loading process. The parameters of the test machine are shown in Figure 2. The user can choose an electronic universal testing machine with a suitable range according to the size of the bending test force and configure the bending test accessories that meet the requirements. If there are other sizes of samples, the test space of the testing machine can be customized.

Figure 1: electronic material testing machine

Figure 2: specification of electronic material testing machine

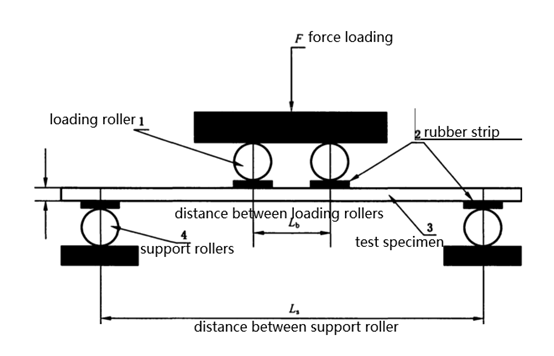

4.2 Test fixture for flexural strength of tempered glass, as shown in Figure 3

Diameter of backup roller and loading roller: 50mm

Length of backup roller and loading roller: not less than 365mm

Spacing of loading rollers: 200mm±1mm

Spacing deviation of backup rollers: within 2mm

Figure 3: Reference drawing of the bending test fixture, subject to the final object

5. Flexural Strength Test Procedure

5.1 Use a metal ruler or a steel tape measure to measure the width of the sample, measure 3 times, and calculate the average value, rounded to 1 decimal place in millimeters. Use an outer micrometer to measure 4 points at both ends of the sample, calculate the arithmetic mean, and round to 2 decimal places in millimeters.

5.2 Open the test software, select the test method and create a new test, input the measured width and thickness into the corresponding position on the test software and save it.

5.3 Place the prepared specimen on the bending fixture of the testing machine. When placed, for lightweight physically strengthened glass and glazed glass, the loading surface is the glass surface. The loading surface of other types of light-weight physically strengthened glass can be determined by negotiation. A film can be attached to the surface of the sample to facilitate finding the source of fracture and prevent debris from flying. Place the sample as shown in Figure 3 below. The thickness of the rubber strip is 3mm and the hardness is (40±10) IRHD.

Figure 3: drawing of sample placement for glass bending strength test

4.4 The distance between the support rollers is selected from the table below according to the thickness of the sample.

Thickness t/mm | Distance between support rollersLa/mm |

T<1.5 | 510 |

1.5≤t<2.0 | 600 |

2.0≤t<2.5 | 700 |

2.5≤t<3.0 | 800 |

4.5 Adjust the position of the upper bending fixture through the test software control box. Select the test speed from the test software, and make the loading roller of the testing machine load the sample at an increasing speed of the bending stress of the sample (2±0.4) Mpa/s until the sample fails.

4.6 The test software automatically records the maximum load when the specimen fails

4.7 Observe whether the source of fracture of the specimen is between the loading rolls. If not between the loading rolls, the test should be repeated with a new specimen added. If the fracture source is between the loading rollers, the test results can be output and printed through the test software.

We specializes in the production and sales of electronic and hydraulic universal testing machine,electronic and hydraulic tensile testing machine, bending testing machine, horizontal tensile testing machine, impact Testing machine, concrete cement compression testing machine, compressive and flexural integrated testing machine, pellet compression testing machine, manhole cover compression testing machine, tensile stress relaxation testing machine, etc. Welcome your calling or visit

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服