News

Electronic tensile testing machine failure and maintenance

Electronic tensile testing machine failure and maintenance

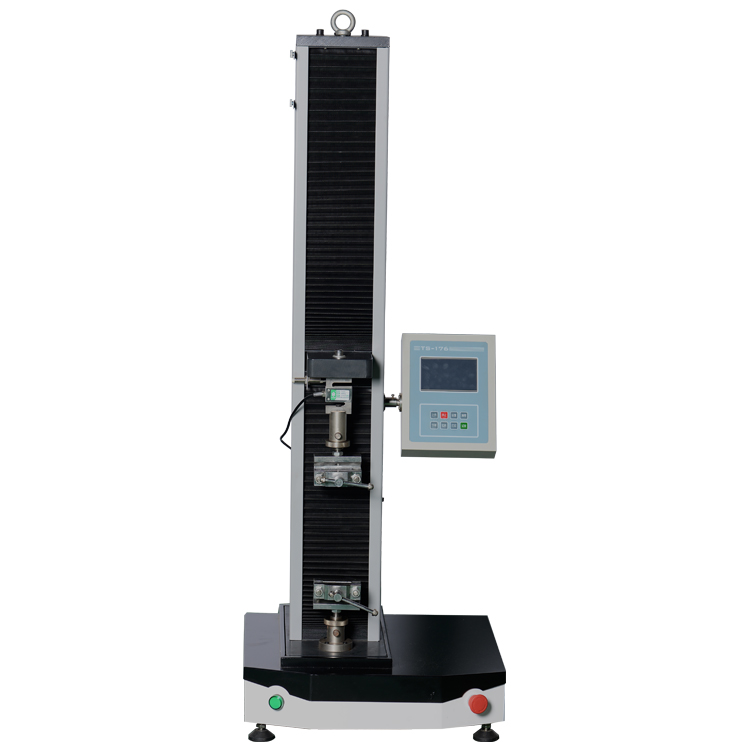

Electronic tensile testing machines are widely used in mechanical properties measuring of industries of petrochemical, aerospace, wire, cable, machinery manufacturing, aluminum-plastic pipes, plastic doors and windows, geotextiles, films, plastics, rubber, ceramics, food, pharmaceutical packaging, wood, paper, metal materials, etc. The electronic tensile testing machine can automatically obtain the test force value, breaking force value, yield strength, tensile strength, compressive strength, elongation at break, tensile modulus of elasticity, flexural modulus of elasticity, etc. During use, the electronic tensile testing machine may go wrong. The following are some common failures and solutions.

Problem 1: The length of the sample is too long, and the travel of the moving beam is not enough

Solution: The size of the sample should be smaller than the crossbeam travel, and at the same time, pay attention to beam speed.

Problem 2: There is a problem with the control system of the testing machine

Solution: consult the manufacturer's after-sales technicians for maintenance

Problem 3: There is a problem with the servo alarm or the sensor force value display

Solution: Replace the load cell

Problem 4: Reverse overload

Workaround: Shutdown, Restart

Problem 5: The data acquisition system of the testing machine is damaged

Solution: replace with a new data acquisition card

Maintenance of electronic tensile testing machine

1. It is necessary to clean and maintain the ball screw of the equipment every six months. When cleaning, use gasoline to scrub it clean and then apply lubricating butter.

2. Prevent high temperature, excessive humidity, dust, corrosive medium, water, etc. from immersing in the machine or computer. Regular inspection to maintain the integrity of parts and components.

3. If the site conditions permit, it is strongly recommended to add a regulated power supply, especially when the equipment is abnormal occasionally.

4. Pay attention to applying anti-rust oil to rust-prone parts or accessories that are not used for a long time, such as clamps, latches, etc. The jaws of the jig or the relatively sliding surface of the jig should be kept clean to avoid bumping. After making a batch of samples, the slag fragments left in the jaws should be cleaned up in time. If the teeth of the jaws are blocked, please use a steel brush dipped in gasoline to clean them, and avoid using sharp and hard tools for cleaning.

5. Usually pay attention to cleaning the working environment of the test, and always keep the test machine and computer clean and hygienic. In particular, machines with special configurations such as hydraulic fixtures and pneumatic fixtures must have a good test environment.

We specializes in the production and sales of electronic and hydraulic universal testing machine,electronic and hydraulic tensile testing machine, bending testing machine, horizontal tensile testing machine, impact Testing machine, concrete cement compression testing machine, compressive and flexural integrated testing machine, pellet compression testing machine, manhole cover compression testing machine, tensile stress relaxation testing machine, etc. Welcome your calling or visit

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服