News

Electronic universal tensile tester for PE pipe tensile strength test

Electronic universal tensile tester for PE pipe tensile strength test

1. introductions of PE pipe

PE pipe is a kind of high crystallinity, non-polar thermoplastic resin. PE pipes have excellent resistance to most domestic and industrial chemicals, and are widely used in building water supply, building drainage, buried drainage pipes, building heating, gas transmission and distribution, gas pipelines, electrical and telecommunication protection casings, industrial use Pipes, household pipes, etc.

2. working conditions of PE pipe tensile testing machine

2.1 The relative humidity is not more than 80% within the range of room temperature 10℃-35℃;

2.2 Install it correctly on a solid foundation or workbench;

2.3 In a vibration-free environment;

2.4 There is no corrosive medium around;

2.5 The fluctuation range of the power supply voltage should not exceed ±10% of the rated voltage;

2.6 The power supply of the testing machine should be reliably grounded; the frequency fluctuation should not exceed 2% of the rated frequency;

3. introductions of PE pipe tensile testing machine

The testing machine consists of a main loading frame, a computer control system and accessories.

3.1. main loading frame

The main loading frame adopts two columns structure and double test space. The motor and reducer are located in the lower part of the main loading frame, which can complete the tensile and compression test, in which the upper space is the tensile space and the lower space is the compression space. The motor drives the precision screw pair to rotate through the pulley deceleration system, thereby driving the middle beam to move up and down to load the sample. The size of the test speed can be controlled by the motor speed control system installed at the bottom of the main loading frame.

3.2. Electrical part

The electrical part is composed of a speed control system and a display measurement system. The machine adopts an AC servo motor and a speed control system, and the speed control system controls the forward, reverse and speed accuracy of the AC motor. The load measurement system consists of a high-precision load sensor, measurement amplifier, A/D converter, regulated power supply, etc. The displacement measurement system consists of photoelectric encoder, pulse width shaping circuit, frequency multiplier circuit and counting circuit. All control parameters and measurement results can be displayed on the screen in real time.

3.3. test fixture

The tester comes with accessories; see packing list

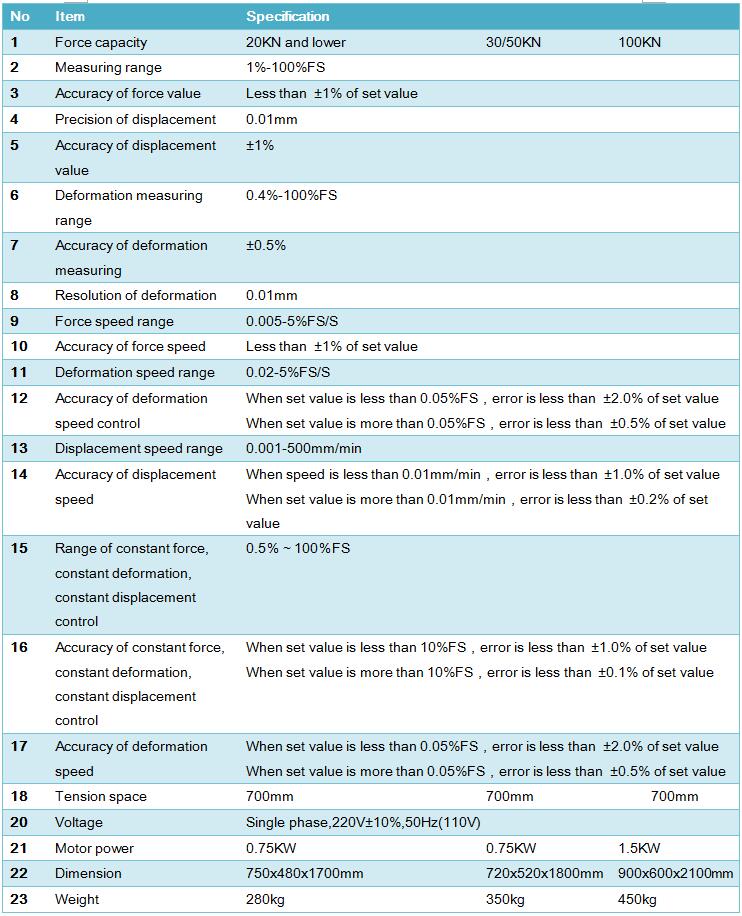

4.specification

our products including electronic universal testing machine,hydraulic universal testing machine,impact testing machine,compression testing machine,horizontal tensile testing machine,manhole cover testing machine,pellet compression testing machine,bending

testing machine,wood based panel testing machine,thermainsulating

materials testing machine,high and low temperating testing

machine,ceramic tiles 3 and 4 point bending and flexural testing

machine,steel strand tensile testing machine,tensile stress relaxation

testing machine,spring tensile and compression testing machine,glass

bending testing machine,welcome consulting

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服