News

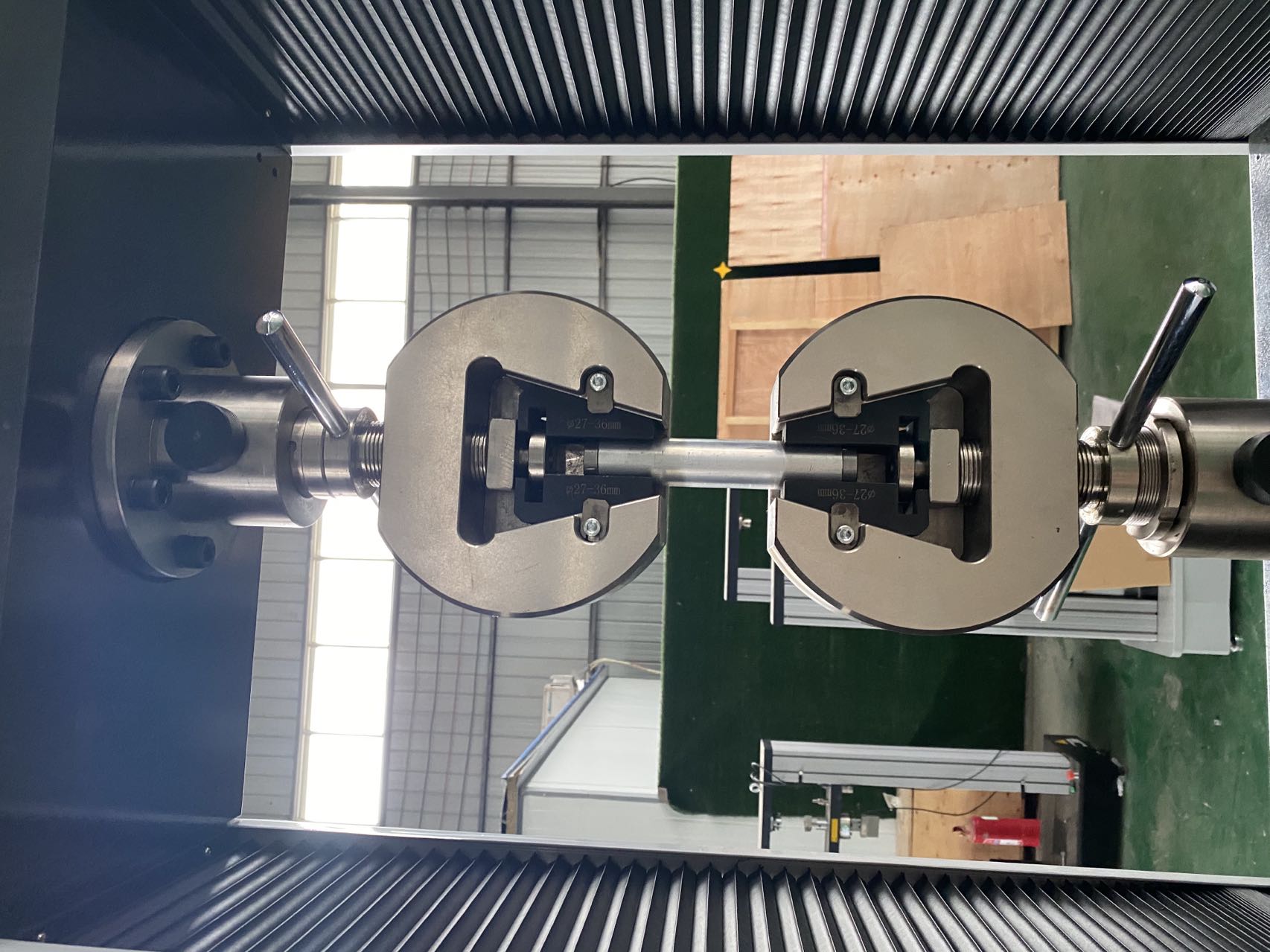

Universal tensile testing machine for steel pipes tensile testing

Universal tensile testing machine for steel pipes tensile testing

Steel pipes are widely used in transport liquids, gases or granulated materials under and above the earth’s surface, in machines and vehicles or in factories. In order to withstand the different stresses to which they are exposed, a broad range of materials and manufacturing processes are used in the production of pipes.

Raw materials and finished pipes testing play a very important role in the area of research and development and in quality assurance during production to ensure the functionality and safety of pipes in the intended use. Starting with the steel melting and ending with the delivery, there are various tests used.

The universal tensile testing machine with capacity ranges from 400kN to 2500kN is often used for testing the steel pipes at the end of the manufacturing process.

The steel pipe tensile testing machine adopts the AC servo speed control system and motor with high speed control accuracy and stable performance as the driving system; the specially designed synchronous toothed belt deceleration system and the ball screw pair drive the moving beam of the testing machine; Windows is used as the driving system. The control and data processing software based on database technology of the operation platform adopts virtual instrument technology to replace the traditional digital tube and oscilloscope, and realizes the screen display of test force, test force peak value, beam displacement, sample deformation and test curve. All operations can be completed by mouse input on the computer screen, with a good man-machine interface and convenient operation; the dual-channel full-digital program-controlled amplifier inserted in the PC realizes the real physical zero adjustment, gain adjustment and The automatic shifting, zeroing and calibration of the test force measurement does not have any analog adjustment links, the control circuit is highly integrated, and the mechanical adjustment devices such as potentiometers are completely eliminated. The structure is simple and the performance is reliable. The comprehensive application of the above technologies ensures that the machine can realize closed-loop control of parameters such as test force, sample deformation and beam displacement, and can realize constant force, constant displacement, constant strain, constant velocity load cycle, constant velocity deformation cycle, etc. test. Users can use the PC expert system to independently set control modes such as constant stress, constant strain, and constant displacement, and switch between various control modes smoothly.

our products including electronic universal testing machine,hydraulic universal testing machine,impact testing machine,compression testing machine,horizontal tensile testing machine,manhole cover testing machine,pellet compression testing machine,bending testing machine,wood based panel testing machine,thermainsulating materials testing machine,high and low temperating testing machine,ceramic tiles 3 and 4 point bending and flexural testing machine,steel strand tensile testing machine,tensile stress relaxation testing machine,spring tensile and compression testing machine,glass bending testing machine,welcome consulting

Categories

Contact Us

- +86-18615632092

- wtbequipment@hotmail.com

- sophie-tester

- +86-18615632092

售前客服

售前客服